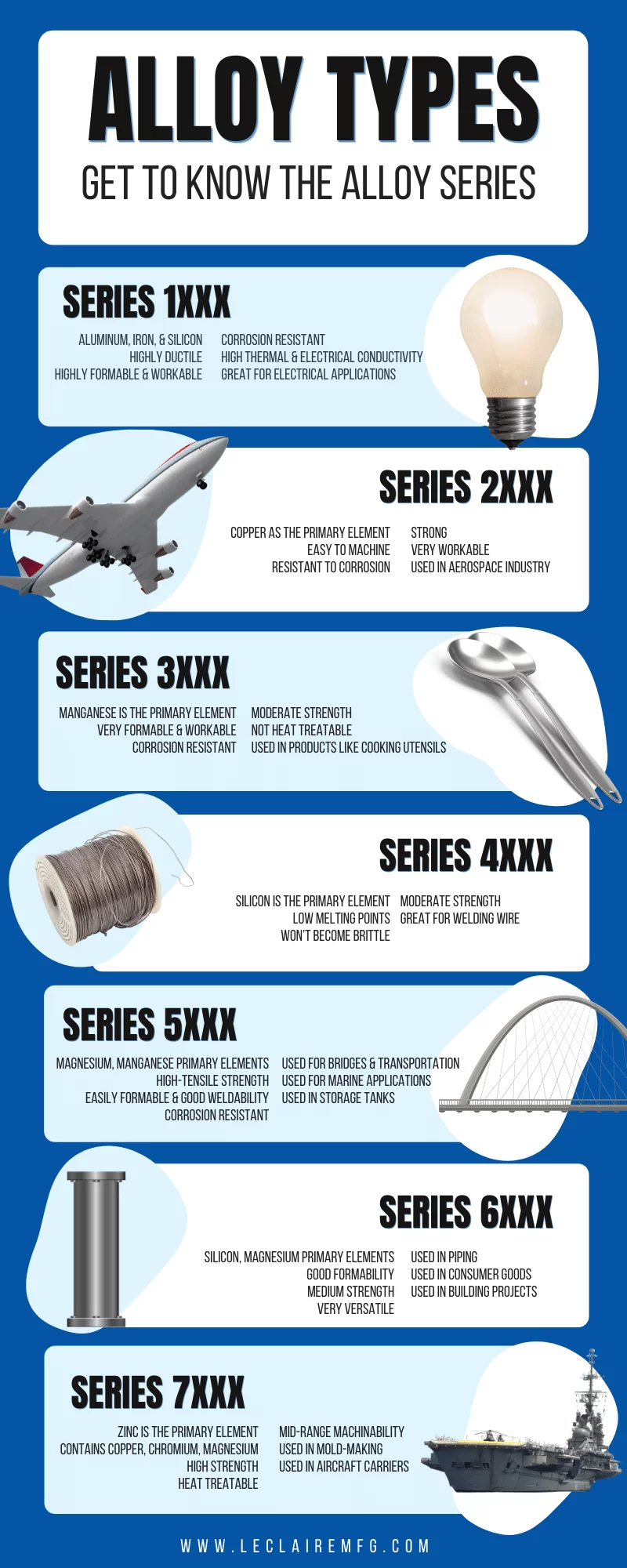

Aluminum is an excellent choice for machining because it is easy to shape. It’s a better choice for many projects because it is more machinable than other metals like steel. Because aluminum is readily available, and easy on equipment as well as cost-effective, manufacturers choose aluminum for machining projects. But how do you know what aluminum alloy is the one for your specific project or application?

Choosing an Aluminum Alloy

The first step is understanding the common characteristics of the different aluminum alloys available. Aluminum is soft, lightweight, and abundant. It can be used to make aluminum sheeting, aluminum plates, or aluminum bars. There are numerous alloys that may lend themselves well to your project. But how to do you know the aluminum alloy to choose? Understanding the different series of aluminum alloys as well as their strengths can help you make the right choice. Our team can also advise you. Read about each series below and let us know if you have questions.

Series 1xxx

Consisting of 99% pure aluminum, this series contains silicon and iron as well. It can easily be drawn out into a thin wire and therefore is used frequently in electrical projects or for chemical applications. Two other factors that may be appealing (or necessary!) are the fact that series 1xxx alloys are resistant to corrosion with low mechanical properties. This alloy is easy to form, and very workable.

Series 2xxx

The primary element in the Series 2xxx alloys is copper. You’ll hear them referred to as copper alloys. Their “trait” that is most appealing and what they are most well known for is their excellent machinability. It is less reliable in the areas of corrosion resistance and weldability. Because of the strength of these alloys, however, they are used frequently in aerospace/aircraft.

Series 3xxx and Series 4xxx

Frequently used in building and architecture, the Series 3xxx alloys are primarily manganese and are well known for formability and medium-grade strength. The Series 4xxx alloys are primarily silicon and have a lower melting point so they are less brittle than other alloys. They are also frequently used in the architecture industry.

Series 5xxx

The primary two elements for Series 5xxx are magnesium and manganese. They hit the trifecta of being strong, formable, and corrosion-resistant. You’ll find these alloys in bridges and other transportation projects. They are also commonly used in the marine industry.

Series 6xxx

Versatility makes the Series 6xxx alloys very popular. Silicon and magnesium are the main alloy elements for this Series. They fall in a mid-strength range but are highly formable and offer great corrosion resistance which makes them popular in numerous segments of industry including pipes, electrical components, and even some consumer products.

Series 7xxx

Strength is the name of the game for Series 7xxx. The alloying elements include zinc, copper, chromium, and magnesium. This Series offers a very high level of strength but is not known for easy machinability. Because of its uses for making molds, it is commonly used by our team. Because of the high level of strength, this Series is found in almost all industries including, but not limited to, automotive, aerospace, marine, and machinery manufacturing.