Every day most of us see scores of pieces either created via sand casting or which at least had a sand cast prototype. It is among the most cost-effective and versatile of the casting processes. In this article, we’ll attempt to take a comprehensive look at the process behind sand casting, as well as its many and varied uses.

What is Sand Casting?

Did You Know?

The history of sand casting long predates modern manufacturing methods. The ancient Chinese dynasties were already using a variation employing clay molds more than 3,000 years ago.

Let’s start by addressing the second part of the term first. Casting is a process by which molten metal is poured or injected into a mold in order to produce a finished part, product or even work of art.

As for what differentiates sand casting from other casting methods, you might have already guessed it is right there in the name. The molds in sand casting are created using tightly packed sand.

Sand casting is a method of producing metal pieces from a mold made of tightly packed and bonded “sand.” The mold is formed around a pattern and then molten metal is poured into the mold in order to produce the finished part.

What Makes Green Sand Casting ‘Green’

One of the most commonly used types of sand casting, and the one we use at LeClaire Manufacturing, is known as green sand casting. What, you may ask, makes it green?

Well, the sand used isn’t naturally green nor is it died green. The last name of the inventor of the technique isn’t Green either.

And no, it has nothing to do with the environment.

What makes green sand casting “green” is the same thing that makes wood “green”: moisture. Water is added to the sand as part of the mold making process.

What is Sand Casting ‘Sand’ Made From

When most people think of sand, they probably think of the beach. As anyone who has ever seen a sand castle built and then collapse can tell you, however, while that sand can be molded into plenty of shapes, it doesn’t exactly stand up well under pressure.

That’s why there is more to the sand casting ‘sand’ than what you might find at the beach.

The primary component is indeed fine, silica-based particulate.

Or, in less scientific terms, sand.

In order to create molds strong enough to hold up under the casting process as well as produce precise castings, a bonding component is added to the mixture. This binding agent is generally a type of clay, usually either bentonite or kaolinite. This gives the sand the additional properties it needs to become an effective mold-making material.

What is the Sand Casting Process?

1. Build a Pattern

The sand casting process doesn’t start with the sand. Trying to sculpt a mold freeform probably wouldn’t be terribly, well, precise.

For that precision, we first have to make a pattern.

A sand casting pattern can be made up from any number of materials, ranging from wood to plastic to rubber. It just needs to be strong enough to hold its shape through the mold-making process and easy enough to work with to achieve the desired level of precision and complexity with the mold.

2. Build a Mold

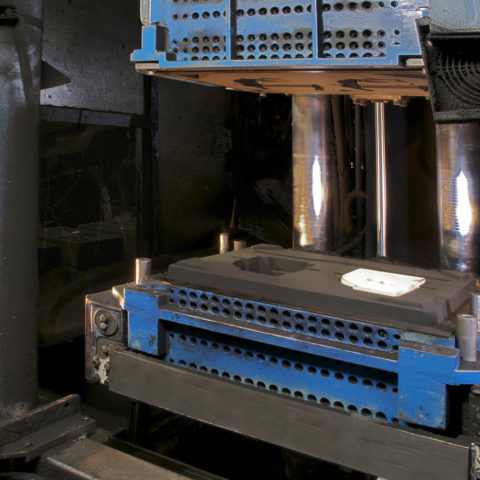

Once you have a pattern, then you can start on the mold. The sand is packed tightly around the pattern, in two halves, leaving a cavity where the pattern had been.

Having two halves of a mold that, when put together, form a precise, intricately designed cavity does you no good, however, without a way to get the metal into the mold.

That is where the runners come in.

Runners are built into the mold at this stage. These are narrow pathways into which the molten metal is poured so that it can flow into the mold cavity.

3. Add any needed cores

If you immediately started pouring metal into the mold at this stage, you’ll end up with a solid hunk of metal shaped exactly like the pattern.

In some cases, this is exactly what you want.

It doesn’t, however, allow for the complexity demanded in most modern manufacturing.

That is why you need cores.

What are Cores?

Cores are pieces inserted into the casting to create hollows in it. For example, cores define the passages within a cast engine block. At LeClaire, we once cast a leak-tight breaking component that included 21 cores for a single cast.

Cores, are created by blowing sand into a “core box” along with a resin that acts as a bonding agent. The core then is cured either through addition of a catalyst or a baking process.

The cores are then placed precisely where they are needed within the mold.

There is a reason that cores are usually made of sand or some other disposable substance regardless of whether you are using sand casting or some other casting process.

It is usually logistically impossible to remove a core in one piece, but you also don’t want to leave it in the final part. So the core is simply broken apart and dumped out of the casting after it has cooled.

4. The Metal is Poured into the Mold

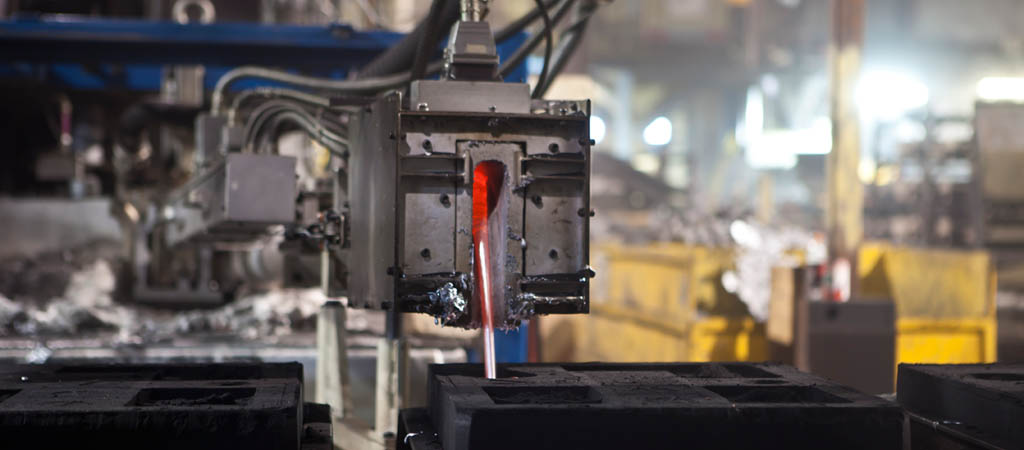

Usually aided only by gravity, technicians (or, more likely these days, machines controlled by technicians) then pour the molten metal into the runners, from which it fills the cavity inside the mold.

5. The Part Is Cooled to Room Temperature

After pouring the molten metal you don’t yet have a part (or the beginnings of a part). You simply have molten metal filling a part-shaped void. In order for it to solidify, you have to bring the casting back to room temperature so it hardens into a solid piece.

There are means that you can use to speed up or slow down this process, depending upon what properties you desire in the part.

6. The Mold is Broken Away

In casting methods in which the molds are reused, the mold at this point would be separated and the part removed.

With sand casting, however, the molds are only used once so they are simply broken apart and the part removed. This is also when any cores are broken up and removed from the part.

7. Finishing Work

The part isn’t finished until the finishing work is done. Any risers or excess material have to be removed and any remaining sand removed from the surface. Some parts also might undergo other processes, ranging from heat treatment to machining.

What Metals are Used in Casting?

What metal you use in casting will be determined by several different factors: strength, weight, toolability, finish, cost.

These answers could lead you in any number of directions: iron, steel, aluminum, bronze, even titanium.

While iron and steel are perhaps the most well known (ever heard of cast-iron?), aluminum is becoming an increasing favorite for casting applications. It is lighter than steel and exists in abundance, keeping the costs lower than some of the other light-weight metal options.

The aluminum used in casting isn’t just aluminum, however. Alloys are typically used, with other metals mixed with aluminum to emphasize certain qualities. Picking the right alloy for the right use is crucial to the casting having the properties you are looking for.

Some provide superior strength, others corrosion resistance. Some are more machinable or ductile. Others have greater degrees of conductivity.

Casting experts like those at LeClaire can work with you to select which aluminum alloy is best for your sand casting project. Let us use our more than 50 years of casting experience to your advantage.

What are the Strengths of Sand Casting?

- It costs less than other casting methods. The sand is simple to form into molds, and after we finish with production, we break it down and use it again. This reduces raw material and other costs in comparison to other casting methods.

- Versatility. The only limits of sand casting involve the kind of patterns that you can create. This is especially true when dealing with a company skilled in the use of cores like LeClaire Manufacturing.

- Accommodates design changes. Because the tooling process is simpler than other casting techniques, sand casting allows for the fastest turnarounds between receiving changes and production.

- Efficient method for prototyping. Need a prototype or parts for testing? Between the lower costs and the efficient tooling process, sand casting produces fast, efficient prototypes.

- Sand casting is ideal for low production applications. While sand casting molds aren’t always ideal for massive production runs because they are only used once, they are an excellent lower-cost alternative for smaller runs. Their ease of creation and versatility give sand casting big advantages.

What are the Weaknesses of Sand Casting?

- Strength: Although much depends on the material used, permanent mold casting can generally produce stronger parts.

- Surface finish: Sand casting, because of the nature of the material used for the mold, typically requires more finishing work to get a smooth finish than permanent mold casting or die casting.

- Large-scale production: While sand casting is great for small production runs given the low tooling costs, the process of needing a new mold for every part eventually will add costs as the size of the production runs rise. The constant mold creation also can lead to wear and tear on the pattern.

Which Industries Use Sand Casting?

While many will utilize different casting methods depending on the part and production run.

Among the industries that use our sand casting services at LeClaire Manufacturing are:

- AGRICULTURE

- RECREATIONAL VEHICLES

- HEAVY TRUCK

- MARINE

- RAILROAD

- VALVES & PUMPS

- MILITARY

- ENGINE COMPONENTS

Contact Us For More Information on Sand Casting

If you want more information on whether sand casting is right for your production needs, contact us at LeClaire Manufacturing.