Advantages Of Casting Process

When it comes to the aluminum casting process, die casting is at the forefront. In fact, die casting serves various industries including, but not limited to, automobiles, trucking, agricultural, and railroad. So what is die casting, exactly? And what are die casting benefits?

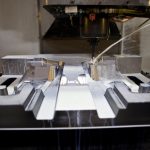

The die casting process is a high-volume production process. Essentially, it is a manufacturing process where molten metal is poured or forced into steel molds. The molds—also known as tools or dies—are constructed using steel. Each mold is meticulously designed for each project. Consequently, this allows each design to be made with accuracy and quality assurance. In addition, aluminum, zinc, and magnesium are the most commonly used die casting alloys.

Die casting can have significant advantages over other manufacturing processes, which often lead to major cost savings, not only in the part price itself but also in the overall cost of production. When you cast apart, you can create complex net shapes, including external threads and complex internal features with minimal draft angles—minimizing secondary operations. You can also combine multiple parts into a single part, eliminating assembly operations and lowering labor costs, with the added benefits of simplified stock control and greater component consistency.

Specific Die Casting Benefits:

-

- Durable components

- Provides complex Shapes

- Tighter and closer tolerances

- High rates of production

- Produces smoother surfaces compared to other casting processes

- Components can be created with thinner walls and various wall thicknesses

- Fewer Steps than other production methods

- Reduces material waste

- Various threads can be included in the cast

Overall, die casting benefits are plentiful. Not only can molds be reused, but aluminum molds offer exceptional service life and are suitable for long production runs. Because of the flexibility of the process, there are numerous components and finished products that can meet specific requirements. Ultimately, this ensures a quality product for all customers involved.

LeClaire Can Help

LeClaire Manufacturing uses the latest technology to create permanent mold castings. Our state-of-the-art facilities are controlled by trained professionals and our mold casting machining bring your designs to actualization. Contact us today to request a quote.